Darren Macintosh

Director - Electrical Engineer

South Africa currently produces over 122 million tons of waste annually. With landfill capacity rapidly diminishing in urban areas, effective waste management is now an imperative.

Waste-to-Energy (WtE) technology not only addresses this critical challenge but also promotes SME business development and creates essential jobs.

SynEnergy is a pioneering waste management enterprise committed to creating a sustainable future through state‑of‑the‑art plasma gasification technology. Our cutting‑edge systems convert municipal solid waste into synthesis gas

(syngas), which is then refined into high‑quality LPG, bio-diesel and methanol for commercial and industrial applications.

At the core of our success is a multidisciplinary team of professional engineers, operators, developers, industrial designers, draftsmen, and experts in finance, compliance, and legal affairs. Together, we blend

technical excellence with innovative thinking to deliver solutions that consistently exceed expectations.

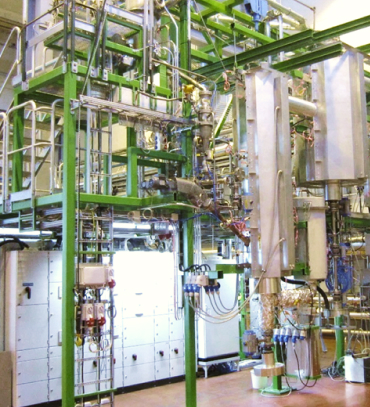

Our advanced plasma gasification process transforms diverse waste streams — such as municipal solid waste, rubber tires, and non‑recyclable plastics — into high‑value outputs including liquefied petroleum gas (LPG) and other biofuels.

At SynEnergy, our circular economy strategy is central to our business model. We are committed to transforming waste into valuable resources, thereby closing the loop on material consumption. Our plasma gasification process

not only generates renewable energy by converting waste into high-quality syngas but also recovers by-products such as vitrified slag and reusable carbon materials.

These secondary outputs are repurposed in industries such as construction and manufacturing, reducing the reliance on virgin raw materials. By integrating waste management with resource recovery and renewable

energy production, we foster sustainable economic growth while minimising environmental impact and landfill dependency.

This holistic approach exemplifies our dedication to creating a resilient and regenerative system that benefits both the community and the planet.

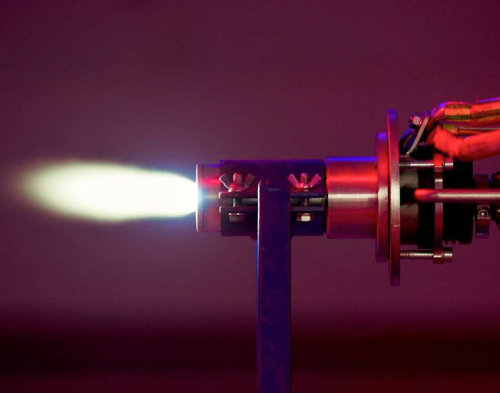

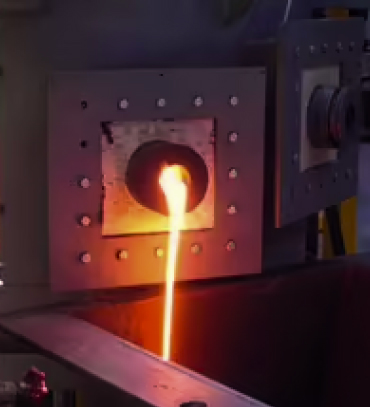

Plasma gasification is an advanced WtE technology that employs plasma arc technology to convert solid waste into energy. This two‑stage process first transforms waste into syngas—a synthetic gas primarily composed of hydrogen and carbon monoxide—and subsequently converts this syngas into valuable energy outputs.

Site Assesment, regulatory compliance and Engineering Assesment

Engeneering drawings are designed for the project over 6-8 weeks.

Plant enegeneering design and legal compliance regulations.

Sign off the project bill of quantities and plant development starts.

Plant construction starts according to the engeneering drawings.

Complete Testing is done and the plant goes live.

Converts a synthesis gas (syngas) into various types of hydrocarbons to produce fuels.

To implement a plant you require a gauarnteed source of feedstock supply to feed into the gasifier.

The Gasification Plant output products can be customised to produce various outputs:

The Plasma Gasification system converts 90% of waste into useable Syngas for product production.

Compliance / Build / Commission

Complience & Licensing

Engineering & Design

Modular Plant Sizes: 5t - 400t P/D

Drawings & BOQ

Construction & Development

Commision Plant

Daily Operations, Maintenance & Commercialisation

Waste Sorting Area

Plasma Gasification Plant

Plant Maintenance Workshop

Brick Manufacturing Plant

Plant Technology Control Room

Plant Testing Laboratory

Factory & Commercial Offices

Product Storage Facilities

Converting Waste to Energy

Municiple Solid Waste (MSW)

Rubber Tyres

Non-recyclable Plastics

Chemical Waste

Medical Waste

Produce: LPG, Diesel & hydrogen

Dive into the latest advancements and breakthroughs in waste-to-energy technology. Our industry news section keeps you informed about sustainable solutions, market trends, and regulations shaping the future of waste management.

learn moreThe District Office Park, 1st Floor, 8 kikuyu Road, Sunninghill, Sandton, 2191.

Office Telephone : +27 0 79 691 2166

WhatsApp : +27 0 76 910 9802

Email: info@SynEnergy.group

Technical Enquiries: lee@SynEnergy.group

Trading Hours : Mon-Fri: 8am to 6pm

Business Enquiry:

Please fill in your company details and business requirements below, and we will be in touch.